The concept of digital transformation is paramount in the development of rail transport. Meanwhile, emerging technologies represented by the Internet, IoT, big data, cloud computing, AI, robotics, new energy and new materials are accelerating their integration with rail transport.

As one of the systematic solutions to realize the digital transformation of the industry, intelligent operation and maintenance plays an important technical support and guarantee role in improving the operation and management level of rail transportation and realizing the cost reduction and efficiency increase of operation. The intelligent inspection robot is one of them.

The application of intelligent inspection robot can easily solve the following intractable problems encountered in railway operation and maintenance:

1. Unable to inspect in time

Manual inspection can not achieve full coverage, can not find equipment hidden dangers in time, but the intelligent robot can inspect 24 hours a day without dead angle.

2. Diagnosis error

Manual inspection and manual recording are prone to errors, which affect the accuracy and detection efficiency of subway fault diagnosis, while intelligent robots effectively use big data and cloud computing analysis to diagnose faults in time;

3. High labor cost

Intelligent robots can realize remote inspection. The inspection data can be transmitted from the monitoring point to the monitoring center in real time, fully realizing the unmanned operation mode, which greatly saves a lot of manpower and material costs in the subway operation and maintenance work.

As one of the leading robot manufacturers and developers in China, SHENHAO is committed to providing professional robotic solutions in the field of smart robotic inspection in railtranportation, power grid, oil and gas chemical industry and other industries.

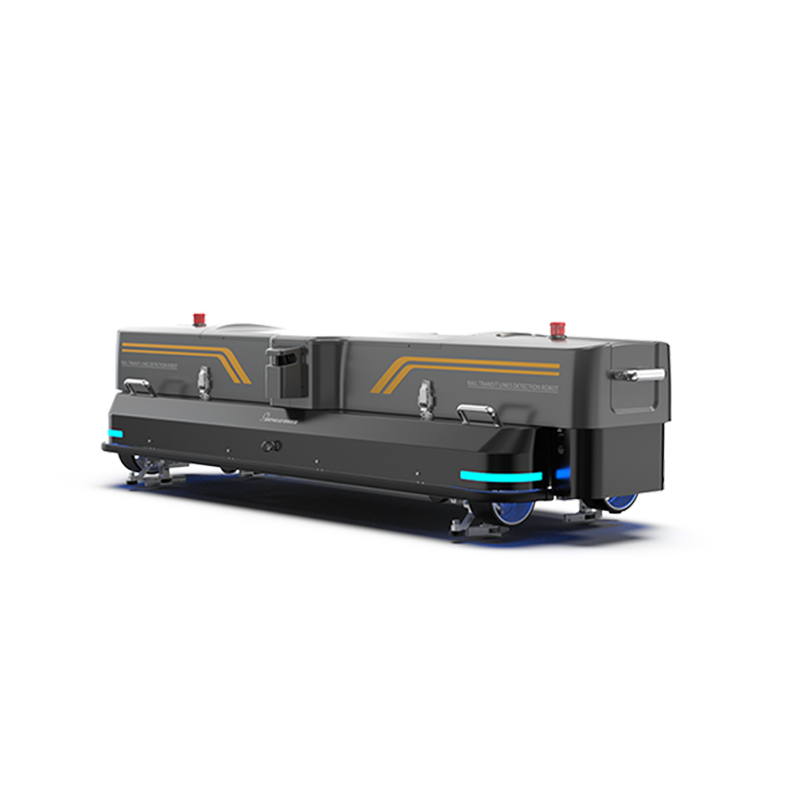

SHENHAO Railway Inspection Robot RIIS1005 adopts comprehensive detection method, with functions covering the main work of current line inspection, dynamic detection, offline analysis of edge computing, and real-time output of detection results.

Dual-track Type Ultrasonic Internal Rail Flaw Detector independently developed by SHENHAO Technology has been proven effective at finding on the order of 100% of the internal defects in rail before something catastrophic happens. This NDT equipment allows for continuous inspection of railway track at up to 15km/h (running speed 20km/h).

At present, SHENHAO’s railway intelligent inspection robots have successfully participated in the O&M teams of railway and urban subway in China and many others countries. The inspection effect is very satisfactory. They can better ensure the normal operation of the subway and railway, and promote the O&M of railway transportation to an intelligent and unmanned era.